By integrating a unified digital platform, we break down information silos and achieve end-to-end precision management—from order and procurement to spinning, weaving, dyeing, finishing, and warehouse delivery. This transforms traditional experience-dependent production into a data-driven intelligent decision-making model,

ultimately reducing costs, improving efficiency, and enhancing core competitiveness.

Quality

Supervision

Production Visualization, Optimized Scheduling (APS), Reduced Downtime, Rapid Response to Rush Orders, Improved OEE.

Cost & Material Control

Accurate BOM & Consumption Calculation, Precise Grey Fabric/Yarn Management, Reduced Dye-Chemical Waste, Detailed Cost Accounting, Lower Inventory Capital.

Quality & Traceability

Full-Process Quality Monitoring (QMS), Bidirectional Traceability (Raw Material → Finished Product, Finished Product → Raw Material), Rapid Issue Localization, Enhanced Product Consistency.

Supply Chain & Customer Service

Supply Chain Collaboration, Accurate Delivery Date Commitment, Enhanced Delivery Experience, Electronic Documentation.

Data-Driven Decision & Intelligence

Data-Driven Decision Making (BI), Core Platform for Automation Equipment and Smart Manufacturing Integration.

Integrated IoT devices collect real-time data on loom speed, downtime, and output. Automatically calculate Overall Equipment Effectiveness (OEE), enable precise yarn inventory management, generate automated quality analysis reports, and accurately predict and confirm delivery dates.

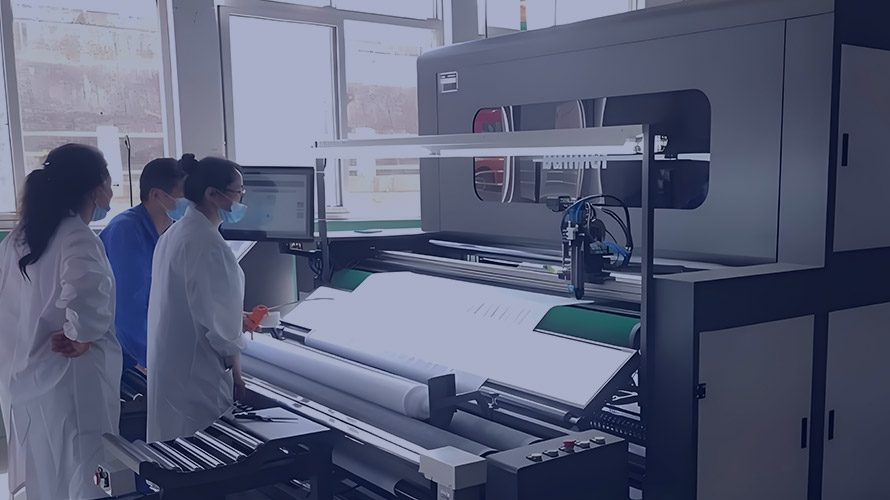

Enter defect length and location on computer: data is instantly recorded in the system, automatically grades and classifies fabric rolls with unified standards, generates visual quality reports, provides data-driven decision support, and enables continuous quality improvement.

Functional Fabric Expert, Green Partner

for Global Apparel Brands.